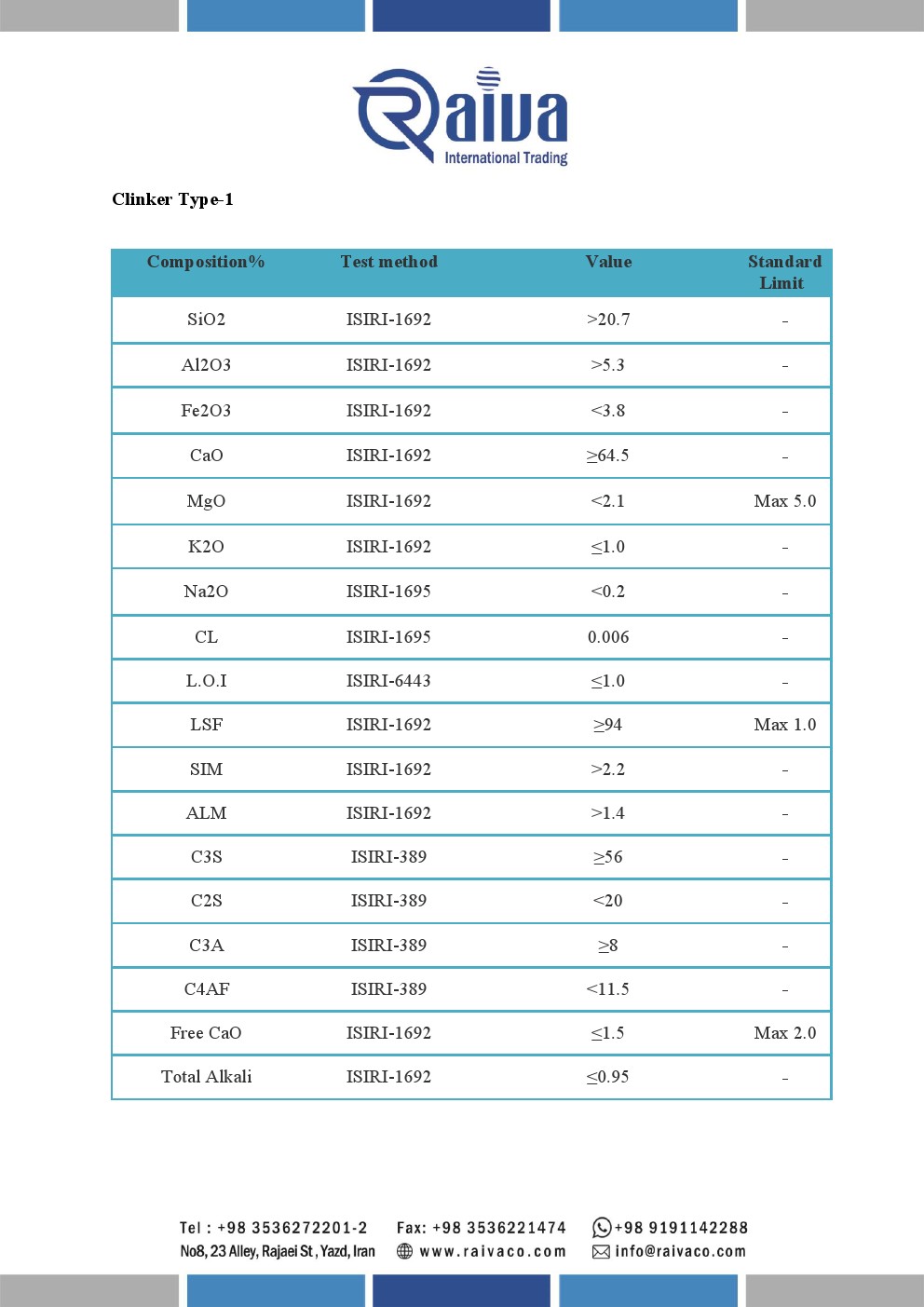

Clinker Type-1

Portland cement clinker is made by heating, in a kiln, a homogeneous mixture of raw materials to a calcining temperature, which is about 1450°C for modern cements.

The aluminum oxide and iron oxide are present as a flux and contribute little to the strength. For special cements, such as Low Heat (LH) and Sulfate Resistant (SR) types, it is necessary to limit the amount of tricalcium aluminate (3 CaO•Al2O3) formed.

The major raw material for the clinker-making is usually limestone (CaCO3) normally; an impure limestone which contains clay or SiO2 is used.

The CaCO3 content of this limestone can be as low as 80%. Secondary raw materials (materials in the raw mix other than limestone) depend on the purity of the limestone. Some of the materials used are clay, shale, sand, iron ore, bauxite, fly ash, and slag. When a cement kiln is fired by coal, the ash of the coal acts as a secondary raw material. Mixed with a second material containing clay as source of alumino-silicate.

Raiva Trading able to deliver clinker products based on customers’ requirements.

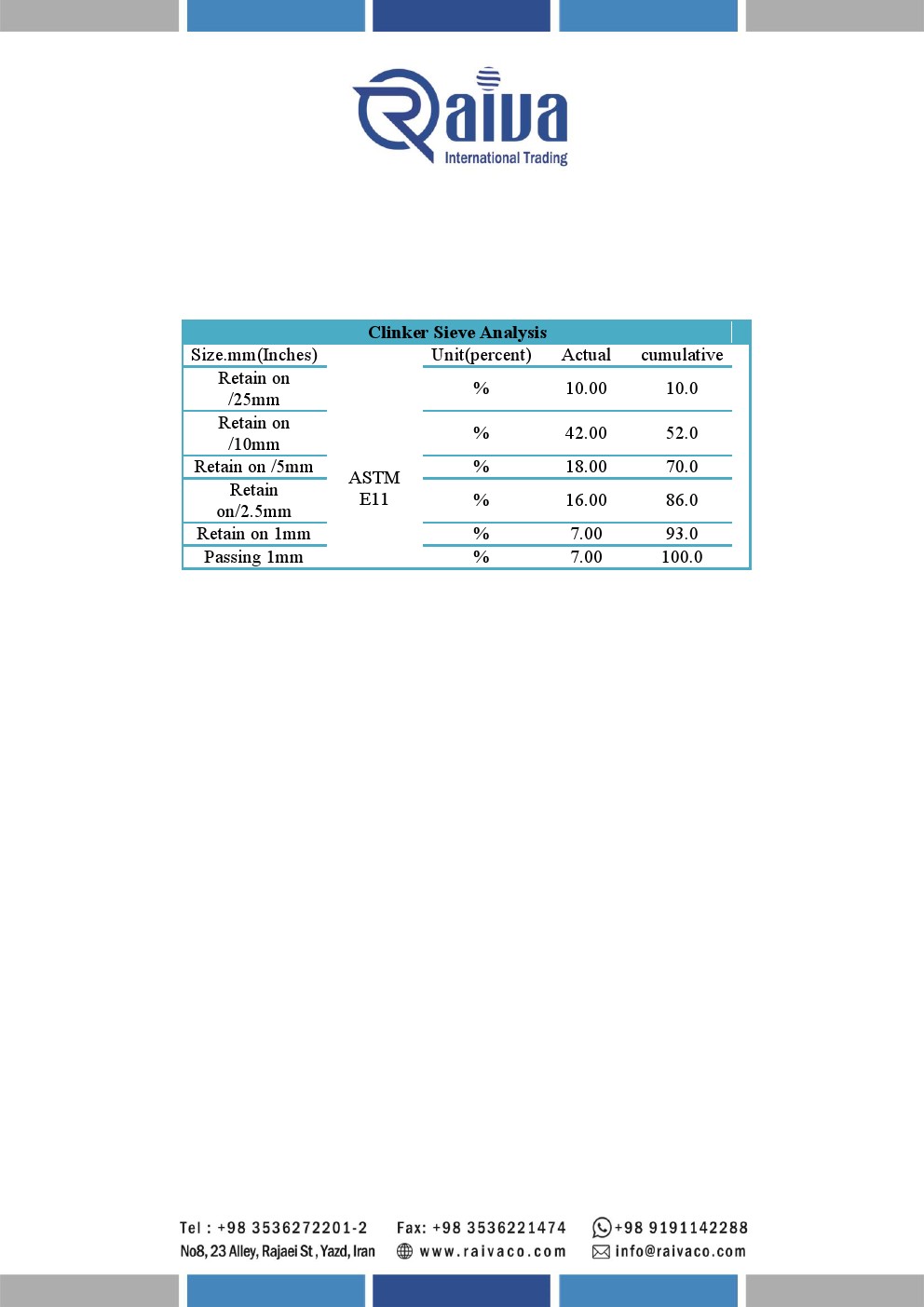

Analyze Report